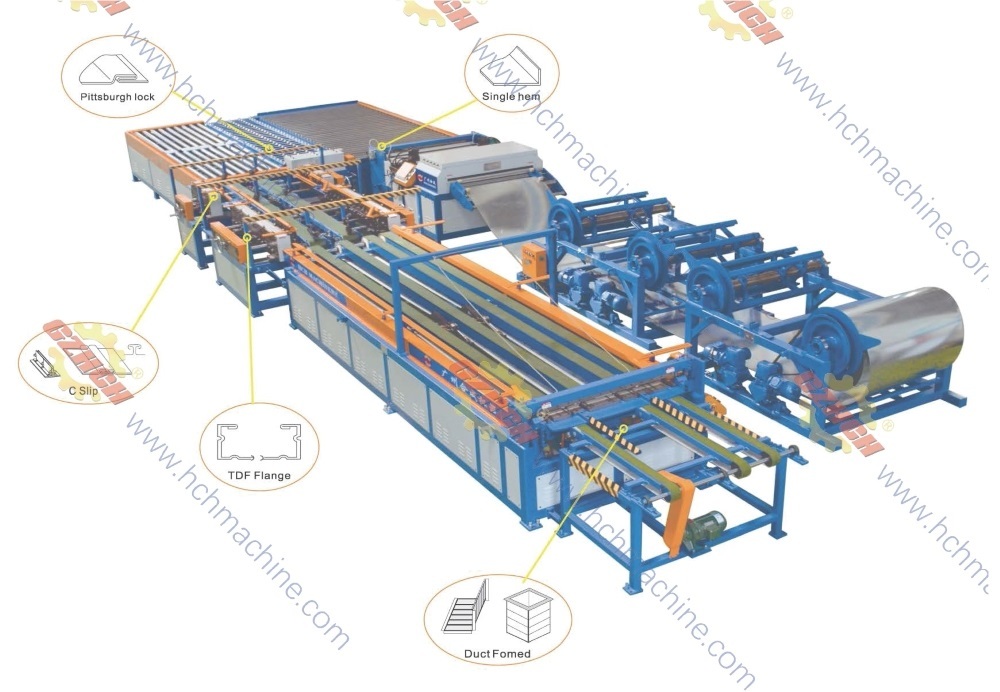

Auto Duct Production Line 7

GZHCH Automatic CNC Duct Production Line is our latest coil line. With U-shaped structure, it reduces time of plate passing period which achieves the productivity of 20-25 seconds per piece. The design adopts the Duct Line III as the main brain, the Pittsburgh Seam after processing is in the front. When producing large-size duct, the short side bent first, which is more suitable for the seam closing.

Keywords:

Category:

Advantages of GZHCH Product :

★ Profound experience in HVAC Ducting Machinery (Since 1986).

★ Profound experience in Automatic Spiral Duct Forming (Since 2004).

★ Profound experience in Automatic Duct Production Line (Since 2006).

★ Have the largest inventory for HVAC Duct Making machines in the industry.

★ The real manufacturer with the most complete varieties of HVAC Ducting Machinery in China.

Features:

★ During feeding mechanism with Hydraulic servo system, manipulator helps to ensure stability and speed of the machine, and the accuracy of its locating system.

★ It only takes 20-25 seconds to make one L-shaped workpiece and the efficiency will double compared with the linear type.

★ Daily processing capacity can reach 800-2500 suqare meters.

★ All the rolling reels are made of bearing steel so that the lifetime prolongs by more than 5 times.

★ Under the material-saving mode of CNC system, waste is less than 20 mm per roll.

★ With production memory functions, the production orders can be tracked and checked.

★ The short side bent first, which is more suitable for the seam closing.

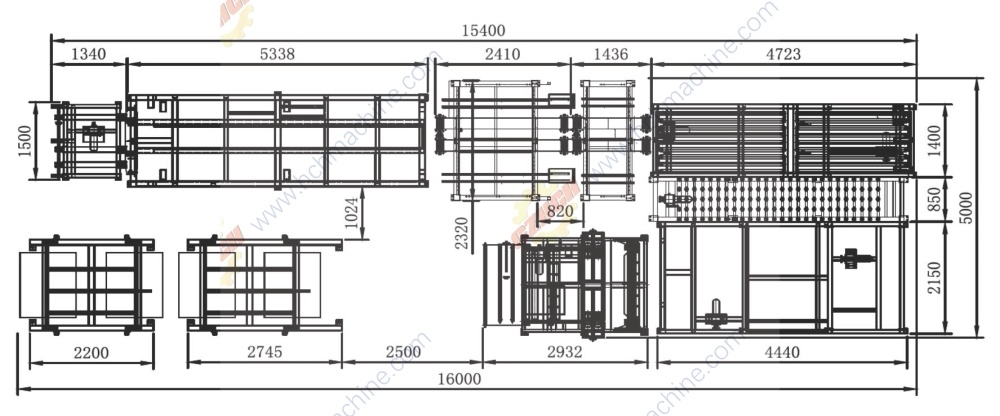

★Auto Duct Production Line 7 Layout Drawings★

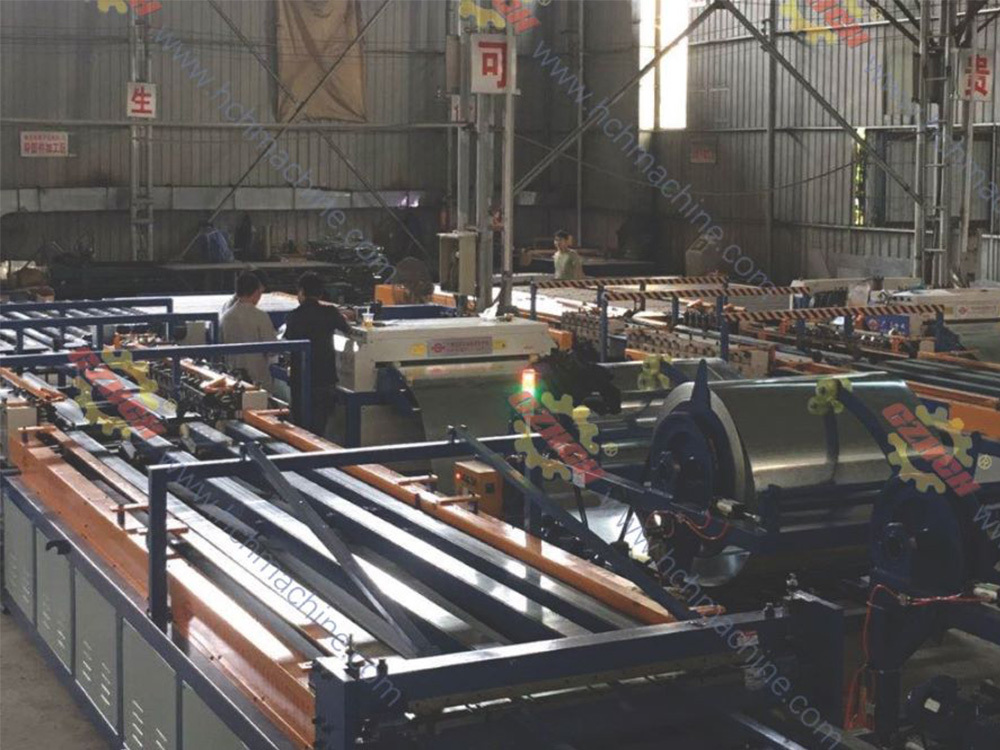

★Auto Duct Production Line 7 Project Site Performance★

|

|

|

|

|

|

|

|

|

|

Basic Configurations Of GZHCH Auto Duct Production Line 7:

1. Dual-Coils Decoiler

2. HCH-III Main Brain

3. Transport Platform A

4. Pittsburgh Seam Former

(Optional: Snap-Lock Former)

5. Transport Platform B

6. Duplex Angle-Iron Flange Former

(Optional: S&D Former)

7. Duplex TDF (TDX) Flange Former

8. Servo Bending Unit

9. Duct Transmission Rack

10. (Optional) Plate-Lamination Device

11. (Optional) Tie Rod Holes (For Duct Bracing) Punching Device

12. (Optional) TDF Flange Holes Punching Device

|

Model |

Thickness |

Material Width |

Coiler Capacity |

Weight |

Dimension(mm) |

|

HCH-VII-1300 |

0.6-1.2 |

1250 |

6000*4 |

16000 |

16000*5500*1300 |

|

HCH-VII-1600 |

1520 |

18000 |

16000*6000*1300 |

||

|

HCH-VII-1300B |

0.6-1.5 |

1250 |

17000 |

16000*5500*1300 |

|

|

HCH-VII-1600B |

1520 |

19000 |

16000*6000*1300 |

||

|

Tips: For detailed parameters, please contact our sales representative. |

|||||

★★★GZHCH company can give you both CNC duct production line machine which can manufacture air duct automatically. We will suggest a whole machines series in accordance with different customers needs★★★

|

|

OUR ADVANTAGES

01 | Customizable

We accommodate custom manufacturing per client specifications

02 | High Quality

The product features an all-steel welded structure.

03 | Widely used

The product finds extensive applications across multiple sectors, including ventilation ductwork systems

04 | After-sales

We offer year-round uninterrupted service with scheduled client follow-ups

OUR ADVANTAGES

Renowned for premium quality, competitive pricing, and reliable after-sales support, we earn consistent customer acclaim.

02 | High Quality

The product features an all-steel welded structure.

03 | Widely used

The product finds extensive applications across multiple sectors, including ventilation ductwork systems

01 | Customizable

We accommodate custom manufacturing per client specifications

04 | After-sales

We offer year-round uninterrupted service with scheduled client follow-ups

Safe

Careful

Effortless

Peace of mind

This is placeholder text

This is placeholder text

Multi-line text content element

HTML language content can be parsed after rich text content is bound to data

This is placeholder text

This is placeholder text

Multi-line text content element

HTML language content can be parsed after rich text content is bound to data

This is placeholder text

This is placeholder text

Multi-line text content element

HTML language content can be parsed after rich text content is bound to data

This is placeholder text

This is placeholder text

Multi-line text content element

HTML language content can be parsed after rich text content is bound to data

This is placeholder text

This is placeholder text

Multi-line text content element

HTML language content can be parsed after rich text content is bound to data

ENGINEERING CASE

MORE PRODUCTS

GZHCH Spiral Tube Forming Machine provide different types of forming mold with different types of cutting device which suit different needs. #1 Tube Mold Type. #2 Steel Strip Mold. With #1 Flying Slitter Device. #2 Plasma Cutting Device. #3 Alloy Saw Cutting Device. Each foming mold and cutting method has its own advantages.

The GZHCH Round Duct Flange Machine (Section Bending Machine),Using Steel Strip Coils, and it forms into an Angle Bar(Round Flange) by rollforming, then cut off the processed workpieces with pleasant appearance and accurate dimensions. It is the perfect choice for ventilation Round Duct Flange Industry.

Also known as Lock Former or Pittsburgh Seamer, it's a multi-functional machine for varying uses in the HVAC ducting industry. Designed for the formation of different types of seams, which are used in the manufacture of rectangular and round ducts, chimneys, gutters. The rolls are made from the highest quality case-hardened steel and can be easily changed.

GZHCH Automatic CNC Duct Production Line is our latest coil line. With U-shaped structure, it reduces time of plate passing period which achieves the productivity of 20-25 seconds per piece. The design adopts the Duct Line III as the main brain, the Pittsburgh Seam after processing is in the front. When producing large-size duct, the short side bent first, which is more suitable for the seam closing.