PRODUCT SEARCH

Quickly find the products you need

SOLUTION

Provide more solutions for ventilation duct equipment!

Classification

Consult Now

Email:

Service Hotline:

Scan code to consult:

Sales Consultation

After-sales Service Consultation

Recommended Products

Neoprene fire-retardant fabric

Neoprene fabric is a high-performance protective material made primarily from premium neoprene rubber (CR), combined with high-strength fiberglass fabric and produced using advanced coating technology. It boasts exceptional weather resistance, oil resistance, acid-alkali resistance, and flame-retardant properties, making it widely used in industrial protection, sealing and insulation, and specialized packaging applications. This product effectively withstands harsh environmental conditions and offers reliable performance over the long term, making it an ideal choice for industrial manufacturing and equipment protection.

Single-layer silicone tube with a soft tip

Custom-length silicone tubing with cuffs—single-layer silicone tubing with cuffs at one or both ends—offers superior airtightness. The soft sleeve tubing features excellent elasticity and, since it contains no internal steel wire, can be securely fixed to the application equipment. Available sizes: 16mm to 254mm; Lengths: Any length up to 4.3 meters.

The double-layer neoprene hose is composed of two layers of neoprene coating bonded to a fiberglass fabric, with spring steel wires concealed between the two layers of fabric. The fiberglass strands on the outer surface are arranged in a helical pattern. It is suitable for high-temperature and low-pressure applications. Operating temperature: -50℃ to 150℃. Available sizes: 16mm to 305mm. Length: 4m per piece.

The double-layer silicone hose is made from glass fiber fabric coated with two layers of silicone. It is resistant to high temperatures, flame-retardant, and chemically corrosion-resistant. It is used in various industries. If you would like a soft end on one or both ends, please click here. Available sizes: 16mm to 254mm; Length: 4m per piece.

Silicone fabric flexible connector

The primary materials are double-layer silicone-coated fiberglass fabric and galvanized steel sheets. Two closely spaced, specially designed seams between the fabric and metal sheets are sealed. Available sizes: maximum metal width—93 mm; maximum overall width—400 mm. Length: 25 m/30 m/50 m per roll.

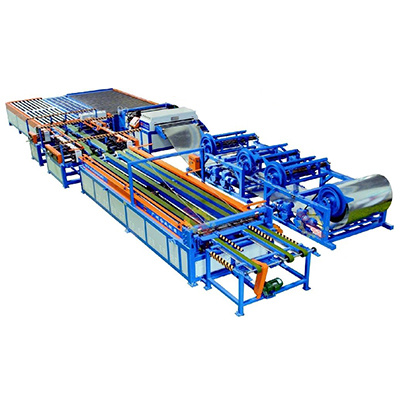

Roll forming machine(customized):Customized for special drawings and samples,to meet the reruirements of various roll forming of fifferent metal sheets. Roll forming machine(customized):Customized for special drawings and sanples,to meet the requirements of various roll forming of different metal sheets.

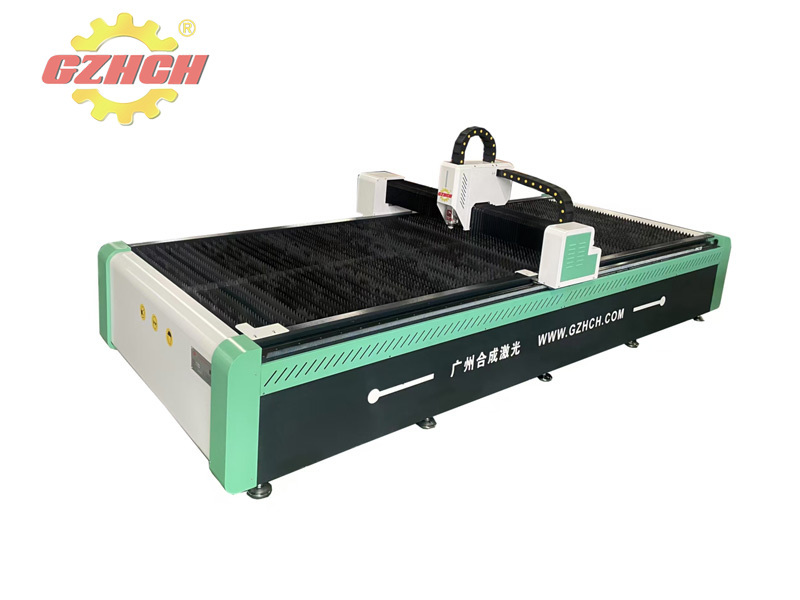

Self-loading laser cutting machine

The self-loading laser cutting machine is a device that integrates laser cutting technology with an automatic loading and unloading system, which can improve production efficiency while ensuring cutting quality and accuracy. Its main components include the laser cutting machine and the automatic loading and unloading system. The latter consists of a robot, loading and unloading position detectors and other components, which are responsible for the automatic loading of raw materials and unloading after cutting.

The duct laser cutting machine uses a high-energy laser beam to irradiate the surface of the wood board, causing the wood board material to quickly melt, vaporize or reach the ignition point, and at the same time blows away the melted or burned material with a high-speed airflow, thereby achieving precise cutting. This non-contact processing method not only avoids the tool wear problem that may occur in traditional mechanical cutting, but also greatly improves cutting accuracy and efficiency.

Guangzhou Synthesizes a new CNC fiber laser cutting machine, offering a choice of laser power supplies from 1000W to 6000W, and equipped with our automatic nesting software. It is mainly used for cutting various rectangular/circular/elliptical pipes and general sheet metal processing.

The GZHCH Latest CNC Plasma Cutting Machine, provides different options for plasma generator cutting source from 45A-125A, and with our Auto Nesting Software, which is mainly used for different kinds of rectangular / round / oval duct blanking.

CNC Angle Steel Fange Welding Machine

GZHCH - One of the biggest manufacturer of CNC Angle Steel Flange Welding Machine in China, the efficient production, welding cycle is only about 10s per flange. Combine with other Duct Making Machine, makes your duct workshop more professional.

GZHCH Spiral Tube Forming Machine provide different types of forming mold with different types of cutting device which suit different needs. #1 Tube Mold Type. #2 Steel Strip Mold. With #1 Flying Slitter Device. #2 Plasma Cutting Device. #3 Alloy Saw Cutting Device. Each foming mold and cutting method has its own advantages.