Automatic Corner Code Production Line

★Professional mold manufacturing,with safe and efficient punching press; ★Feeding and leveling integrated machine,with servo feeder; ★Provide different configurations and flexible solutions.

Keywords:

Category:

Advantages of GZHCH Product :

★ Profound experience in HVAC Ducting Machinery (Since 1986).

★ Profound experience in Automatic Spiral Duct Forming (Since 2004).

★ Profound experience in Automatic Duct Production Line (Since 2006).

★ Have the largest inventory for HVAC Duct Making machines in the industry.

★ The real manufacturer with the most complete varieties of HVAC Ducting Machinery in China.

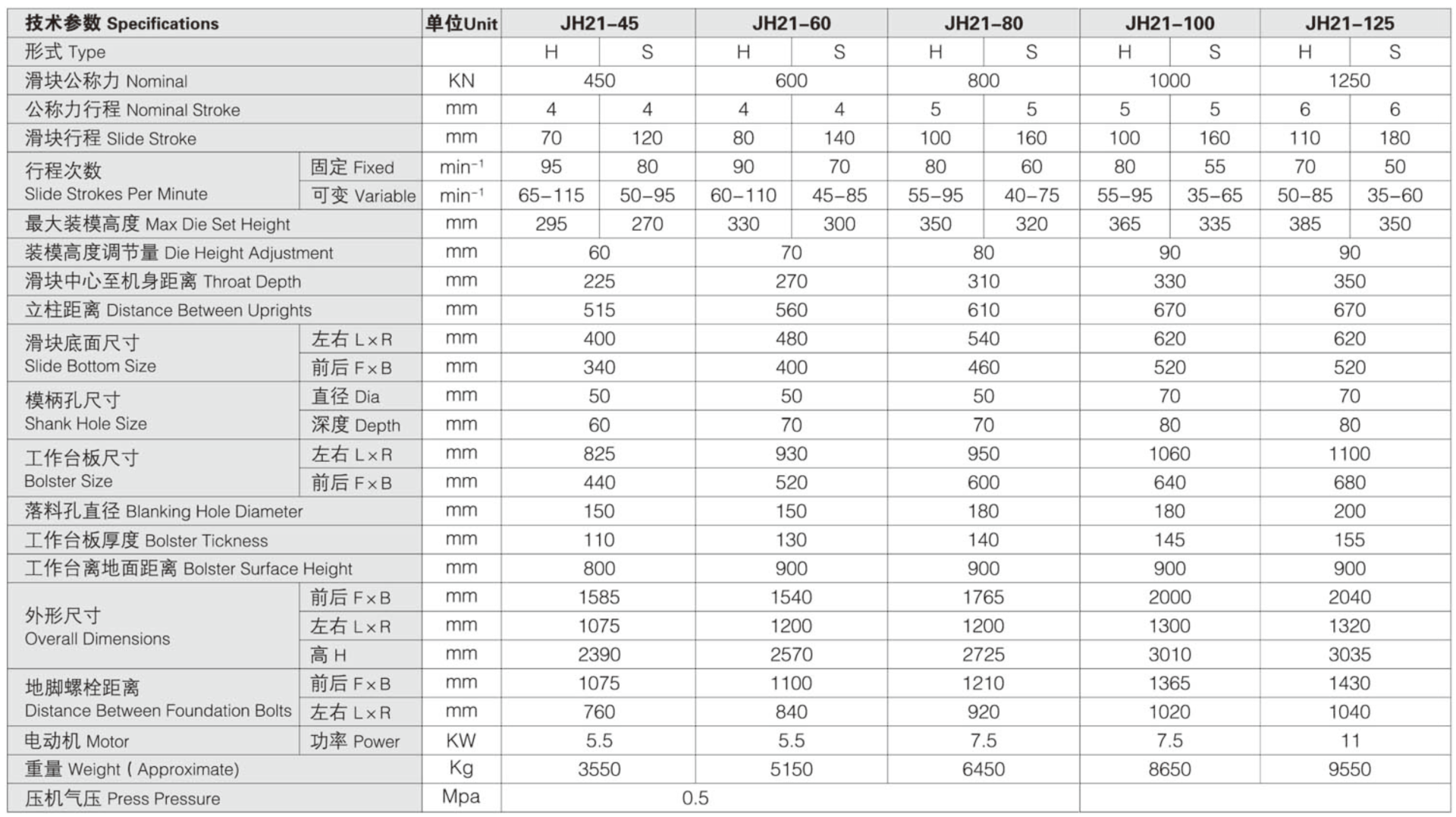

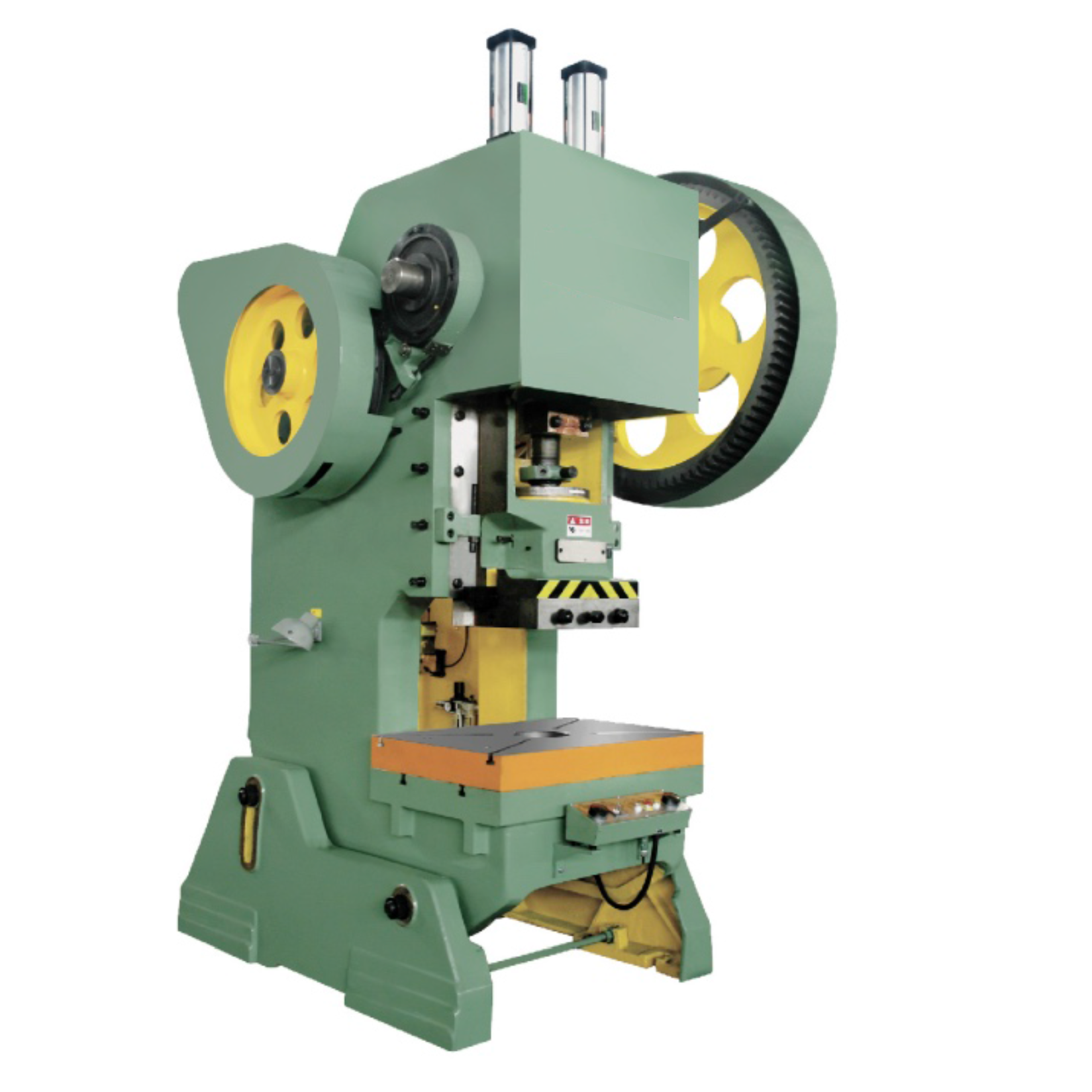

★JH21 Series C-frame Fixed Boleter Press ★

★Features★

★Professional mold manufacturing,with safe and efficient punching press;

★Feeding and leveling integrated machine,with servo feeder;

★Provide different configurations and flexible solutions.

★Standard Equipments★

★Wet clutch(World);

★Hydraulic overload protecting pump;

★Auto lubrication system;

★Manual lubrication system;

★Balance cylinders for slide and upper die;

★Joint for miss-feeding;

★Touch screen;

★Electronic crankshaft angle indicator (JH21-25-80 with pointer);

★Cam controller;

★Die height adjusted motor (JH21-60-400);

★PLC:Programmable logical controller;

★Air source quick connector;

★Absorbing pads;

★Work ing lamp;

★Air blowing;

★Second degree drop;

★Preset counter.

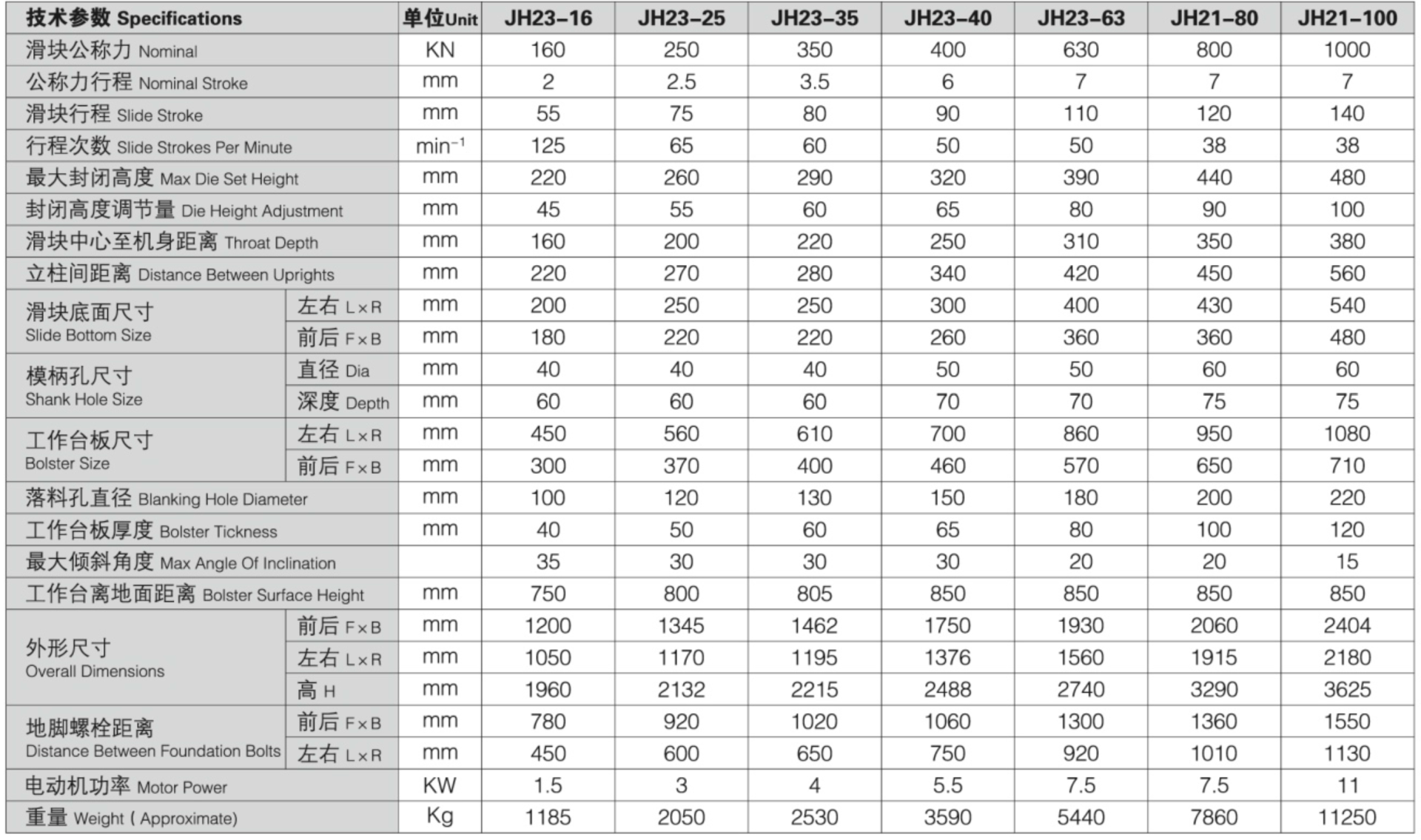

★JH23 Series C-frame High performance lnclinable Press★

★Features★

★The machine features good rigidness,stable precision,sliding block with mechanical overload protection device,and it is safe,reliable and has a long service life;

★The machine adopts combined pneumatic friction clutch-brake,and it features compact structure ,smooth transmission. sensitive action,convenient operation and low noise;

★By means of electrical and pneumatic control,the machine can make inching,single,and continuous punching,as well as emergent brake;

★AII adopts solidify PC concentrated control;

★Featuring high efficiency of automatic production with high performance and reasonable price,JH23 is an upgrade product for J23.

|

★Optional Equipments★

★Light curtain;

★Pnequematic die cushion apparatus ;

★Foot pedal;

★Speed motor,frequency control.

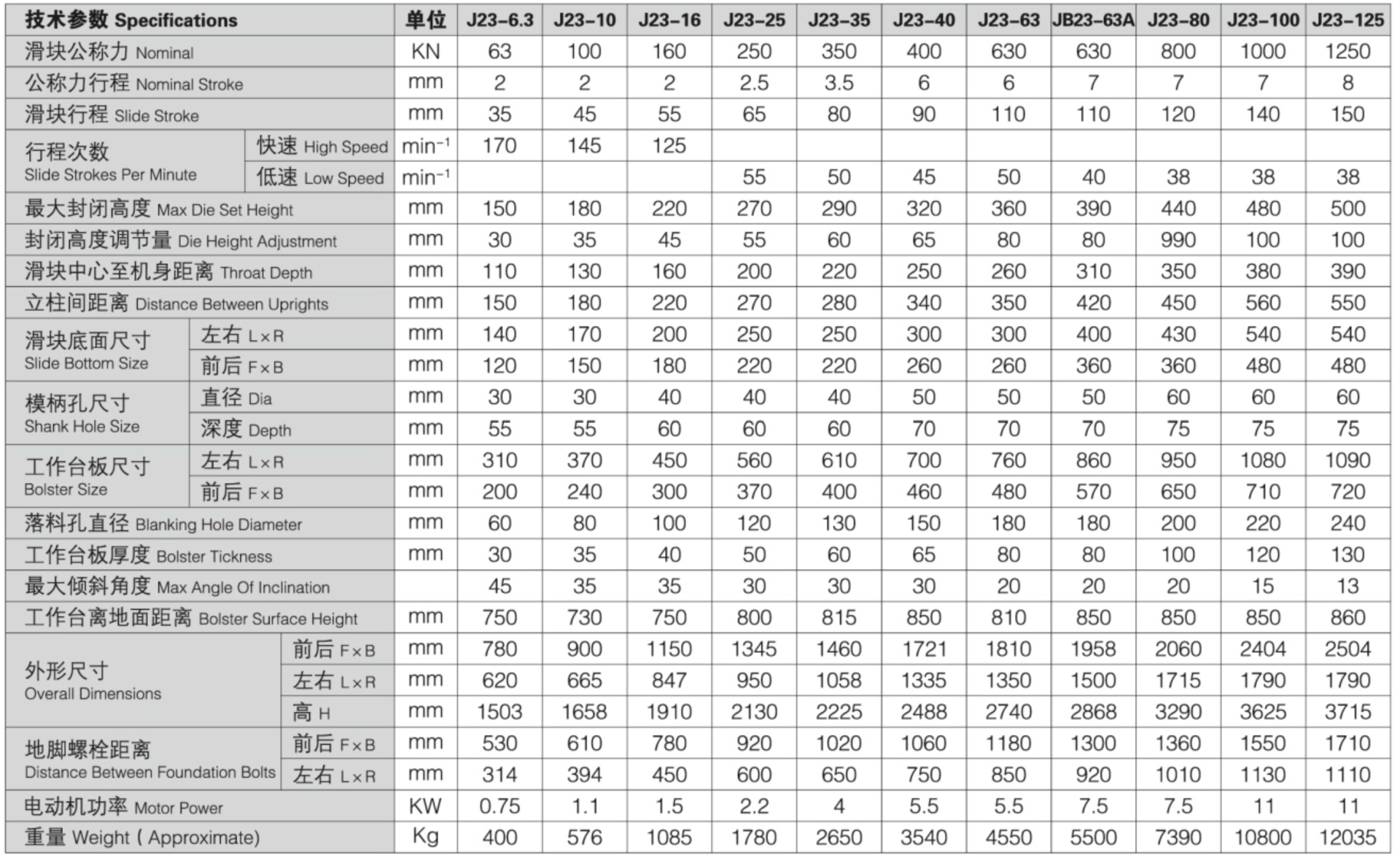

★J23 Series C-frame lnclinable Press ★

★Features★

★This series of press adopts rotating key positive clutch,which has a simple structure and is convenient to operate and maintain,achieving smooth operation,low impact and low noise;

★J23-25 open type inclinable press machine is the first to adopt rol1ing bearing rather than the commonly used sliding bearing (copper bearing) for the transmission gear. making the transmission gear more wear -resistant and avoiding loud noises of gears caused by the quickly worn copper bearing;

★The 80T-Ievel and above press machine all adopt the structure of pneumatic dual balance cytinder ,which has small fluctuation of the balance force and it balances the slider and the upper die,which can cause the lathe unstable. And it can also avoid the clash and noise caused by the converse force of gears in transmission,and avoid accidents caused by the falling of slider when the brake fails or the connecting rod ruptures.

|

★Corner,corner mold,accessories ★

The following accessories can be purchased from GZHCH company:

★★★GZHCH company can give you both CNC duct production line machine which can manufacture air duct automatically. We will suggest a whole machines series in accordance with different customers needs★★★

|

|

OUR ADVANTAGES

01 | Customizable

We accommodate custom manufacturing per client specifications

02 | High Quality

The product features an all-steel welded structure.

03 | Widely used

The product finds extensive applications across multiple sectors, including ventilation ductwork systems

04 | After-sales

We offer year-round uninterrupted service with scheduled client follow-ups

OUR ADVANTAGES

Renowned for premium quality, competitive pricing, and reliable after-sales support, we earn consistent customer acclaim.

02 | High Quality

The product features an all-steel welded structure.

03 | Widely used

The product finds extensive applications across multiple sectors, including ventilation ductwork systems

01 | Customizable

We accommodate custom manufacturing per client specifications

04 | After-sales

We offer year-round uninterrupted service with scheduled client follow-ups

Safe

Careful

Effortless

Peace of mind

This is placeholder text

This is placeholder text

Multi-line text content element

HTML language content can be parsed after rich text content is bound to data

This is placeholder text

This is placeholder text

Multi-line text content element

HTML language content can be parsed after rich text content is bound to data

This is placeholder text

This is placeholder text

Multi-line text content element

HTML language content can be parsed after rich text content is bound to data

This is placeholder text

This is placeholder text

Multi-line text content element

HTML language content can be parsed after rich text content is bound to data

This is placeholder text

This is placeholder text

Multi-line text content element

HTML language content can be parsed after rich text content is bound to data

ENGINEERING CASE

MORE PRODUCTS

Also known as Lock Former or Pittsburgh Seamer, it's a multi-functional machine for varying uses in the HVAC ducting industry. Designed for the formation of different types of seams, which are used in the manufacture of rectangular and round ducts, chimneys, gutters. The rolls are made from the highest quality case-hardened steel and can be easily changed.

GZHCH Automatic CNC Duct Production Line is our latest coil line. With U-shaped structure, it reduces time of plate passing period which achieves the productivity of 20-25 seconds per piece. The design adopts the Duct Line III as the main brain, the Pittsburgh Seam after processing is in the front. When producing large-size duct, the short side bent first, which is more suitable for the seam closing.

The GZHCH Automatic CNC Duct Production Line is our latest Duct coil line machine. With U-type structure, it reduces time of plate passing period which achieves the productivity of 20-25 seconds per piece. Pittsburgh Seam and Single Seam forming separately by Two Lock Forming Machine which makes the Pittsburgh Seam after processing is in the front. When producing large-size duct, the short side bent first, which is more suitable for the Duct Seam Closing and Heavy Gauge Material.

GZHCH Automatic CNC Duct Production Line is our latest Duct coil line machine. With U-type structure, it reduces time of plate passing period which achieves the productivity of 20-25 seconds per piece. It's one of the most popular partners of duct fabrication factories.