What are the safety technical operating procedures for a fully automatic duct production line?

Oct 19,2022

What are the safety technical operating procedures for a fully automatic duct production line?

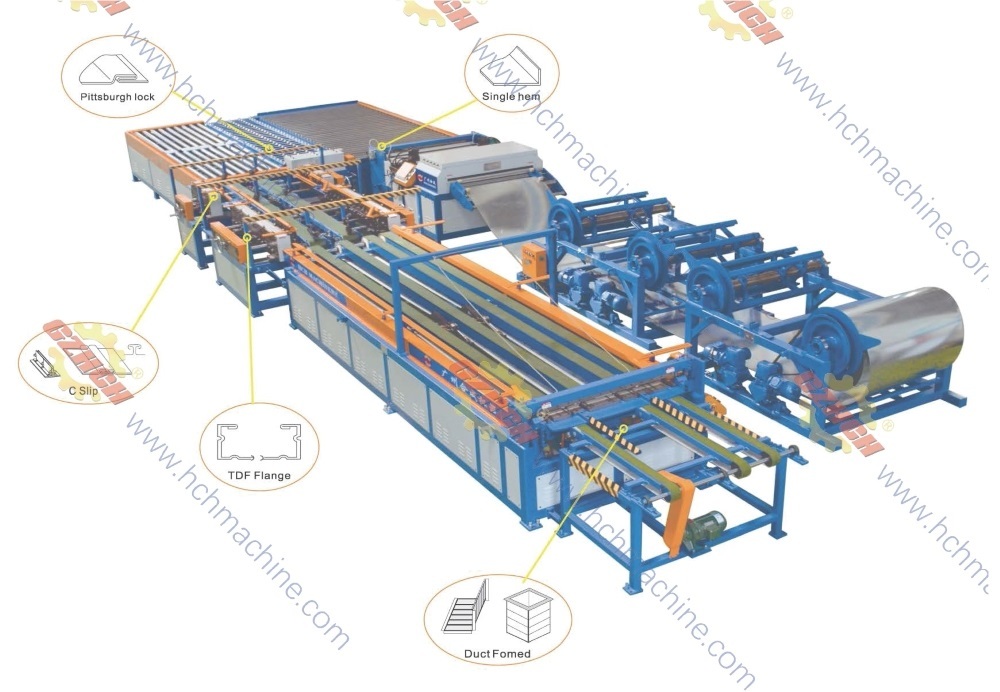

A fully automatic duct production line is a device used to produce rectangular ducts. Its automated production process replaces traditional manual manufacturing; it is automated. So, what are the safety technical operating procedures for a fully automatic duct production line?

What are the safety technical operating procedures for a fully automatic duct production line?

1. The machine should be operated by designated personnel who are familiar with the machine's structure and performance.

2. Regularly check for loose parts and oil leaks each shift.

3. Before starting the machine, check the punching and shearing dies and blades for foreign objects. Only after confirming that there are no foreign objects can the machine be tested.

4. Before starting the machine, check if all parts of the machine are securely fastened to eliminate any concerns.

5. If any special operation or unusual noise occurs during operation, stop the machine immediately, check it, and only operate after troubleshooting.

6. Before starting the hydraulic oil pump, add N46 hydraulic oil to ensure the oil level is above 3/4 of the oil level gauge [approximately 75L]. After the system runs and the oil level drops, add hydraulic oil to the oil level mark again.

7. Before starting the hydraulic oil pump, adjust the pressure of the overflow valve by turning the handwheel counterclockwise, and jog the motor to see if the motor rotates in the correct direction. Do not allow the oil pump to reverse. If there are no special phenomena after running without load for a few minutes, the pressure test can be carried out step by step.

What are the basic configurations of a fully automatic duct production line?

1. Four electric racks and four rolling trays (with a load capacity of 5-7 tons).

2. Leveling, pressing rod, punching tip, adding mold, hydraulic shearing machine (duct secondary line host).

3. Displacement interlocking machine.

4. One electric feeding platform.

5. Double-link common plate flange forming machine.

6. A type of double-acting angle steel flange forming machine.

7. Computer control system and production software suite.

8. A full set of other machine equipment accessories.

What are the functions of a fully automatic duct production line?

1. Linear structure, simple assembly, suitable for standard factories.

2. Servo pneumatic manipulator driven feeding, ensuring stability, accurate positioning, and high speed.

3. High efficiency, high labor productivity, only 20-25s per piece, high efficiency.

4. Fixed bite machine, which can reduce the back-and-forth movement time and improve work efficiency.

5. All rollers are made of GCr15 steel, which is more wear-resistant and has a longer service life.

6. The numerical control system adds a way to save materials. Each piece of material only has one piece of waste less than 20mm, and the length error is 0.5mm.

7. The system with production memory function can view previous production situations.

Duct production must use a duct production line, but due to the specific characteristics of each production line, different production lines will be selected when producing different ducts.

Consult Now

Email:

Service Hotline:

Scan code to consult:

Sales Consultation

After-sales Service Consultation

More News