What are the advantages of a fully automatic duct production line?

Oct 09,2022

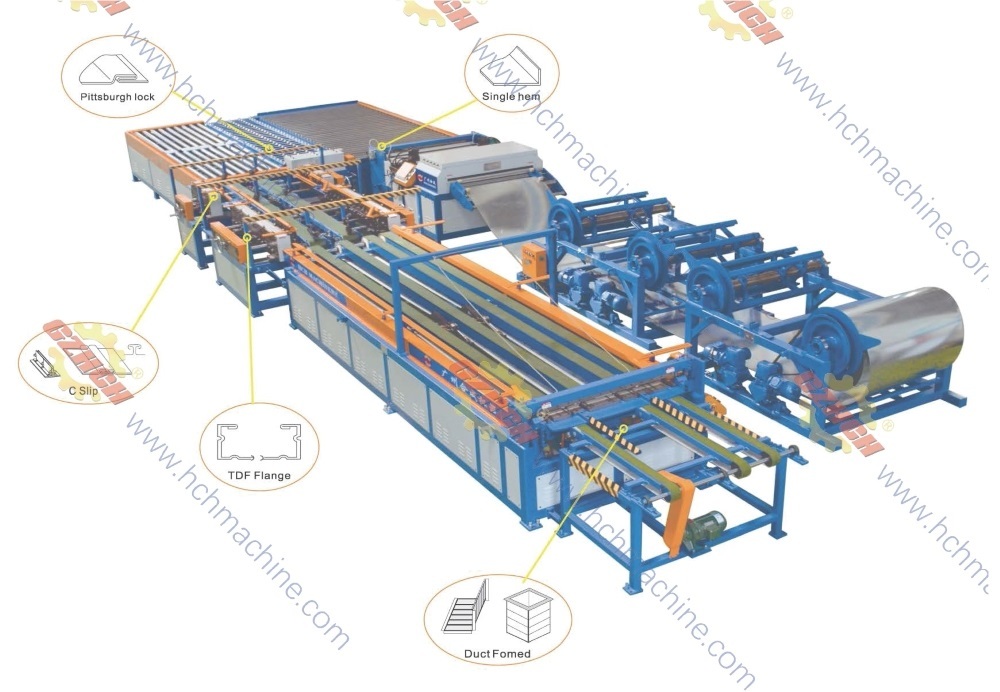

Duct production lines have many advantages in producing ducts, as many of you know. But do you know the advantages of a fully automatic duct production line? Let me introduce them to you below.

What are the advantages of a fully automatic duct production line?

1. Good strength and rigidity.

2. Easy installation, fewer connection points.

3. Low ventilation resistance, low ventilation noise.

4. Can replace some processes that require hot-dip galvanizing.

5. Smooth appearance, no zinc particles or burrs, silvery white.

6. Good corrosion resistance, 24-hour neutral salt spray test.

7. Controllable thickness, can be arbitrarily selected within the range of 5-107m.

8. No hydrogen embrittlement, no temperature hazard, ensuring that the mechanical properties of the material remain unchanged.

9. Design and customize various specifications of ducts according to customer requirements.

10. Completed using hot-dip galvanizing, suitable for various strongly corrosive environments such as strong acid and strong alkali mist.

What is the difference between three-line and five-line duct production lines?

1. Three-line duct production: This equipment mainly performs a series of processes such as uncoiling and shearing.

2. Five-line duct production line: Servo-driven feeding platform, dual-machine linkage flange, folding.

3. In short, the three-line is a semi-automatic duct production line, suitable for small duct processing plants. The five-line uses an automatic generation mode, suitable for large processing plants. In terms of size, the three-line is smaller and can be processed directly on the construction site, but other related equipment is needed to process complete ducts. The five-line duct production line is larger and suitable for placement in a factory. Because it is a fully automatic duct production line, its functions are very complete, and the duct processing efficiency is very high.

What are the production steps of a fully automatic duct production line?

1. Press the duct into a whole, then cut and form it, and press the four corners.

2. The ducts are connected by duct clips, cut into uniform sizes, and then installed.

3. This invention is simple to operate, improves work efficiency, has good dimensions, and high quality.

4. The duct production line can be used with various production equipment: shearing machine. This production line can adapt to high-efficiency production and mass production.

How to inspect a fully automatic duct production line?

1. The duct manufacturing process involves preparing the sheet metal, then feeding the sheet metal into the equipment, adjusting the initial part of the sheet metal, and then completing the manufacturing of the duct mounting holes. Because the material required for a duct is limited, the material needs to be automatically cut to avoid waste.

2. Then proceed to the next process for processing, which can complete the manufacturing of the joint angles.

3. Then there is the bending of the duct. A complete duct production line should have the functions of cutting, compacting (mainly adjusting the sheet metal), cutting (separating the sheet metal from the semi-finished product), and conveying (facilitating entry into the next process).

4. Then there is the crimping and forming function, which is a complete duct production line.

PREVIOUS:

Consult Now

Email:

Service Hotline:

Scan code to consult:

Sales Consultation

After-sales Service Consultation

More News