What are the operating procedures for a fully automatic duct production line?

Jul 28,2022

What are the operating procedures for a fully automatic duct production line?

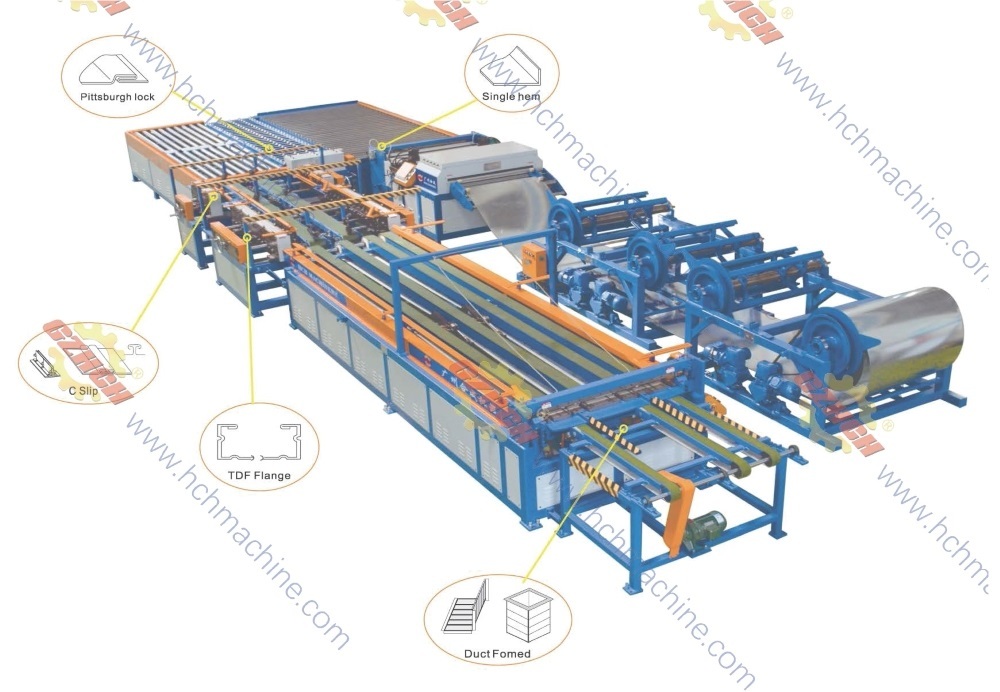

A fully automatic duct production line is the main technical equipment for duct manufacturing enterprises. Determining the technical specifications of the equipment, mastering the maintenance rules for the hydraulic and electrical control systems, and ensuring the normal use of the equipment are all very necessary. So, what are the operating procedures for a fully automatic duct production line?

What are the operating procedures for a fully automatic duct production line?

1. Electric double-disc feeding rack section

The output rack is equipped with a 1.5KW motor, which drives and controls the automatic output, output, and inching feeding functions through a reducer and circuit. It provides good protection for the surface of the sheet metal, avoiding the phenomenon of ordinary feeders damaging the edges of the sheet metal. When changing materials, the user only needs to lift the feeding shaft from the feeding rack, place it in the coil core to be used, and manually tighten the locking ring to complete the placement of the coil. The operation is simple and the material change is convenient.

2. Feeding leveling and crimping machine section

The pressure rods are arranged in five parallel lines, and the pressure rings are made of high-quality steel. After heat treatment, it can meet the pressing requirements of 1.2mm thick sheet metal, and can form five kinds of curvatures and angles at one time, greatly enhancing the rigidity of the formed sheet metal.

3. Corner cutting machine section

The corner cutting section is located at the end of the leveling machine and can be freely adjusted according to the width of the sheet metal. The corner cutting die is very convenient to disassemble and replace. When it is necessary to punch and shear different angles and shapes, only the upper and lower molds need to be replaced, and the power is executed by the hydraulic system.

4. Hydraulic shearing machine section

The shearing section is located between the corner shear and the bite machine. Its functions are: first, to shear the material; second, to cut off the right-angle edge when refueling.

5. Multifunctional seaming machine section

After corner cutting, the sheet metal continues to advance. When the preset length is reached, the seaming machine automatically passes through, cuts and shapes the oriental bone and right-angle bone, automatically returns to its original position after arriving, completes a cycle, and realizes the seaming function.

6. Double-machine linkage self-forming flange machine section

When forming duct flanges, the double-machine linkage flange machine can be used independently or with a large duct production line. Compared with a single machine, the processing efficiency is greatly improved, the forming is stable and beautiful, and it can form a strong processing capacity. It is the primary equipment under the conditions of large duct processing volume, tight processing time, and few processing personnel. The metal sheet can be formed on both sides or one side, especially suitable for forming with a metal sheet thickness of 0.5-1.5 mm, and the workpiece width can be adjusted, with an adjustment range of 600-1500 mm, suitable for professional batch production of ducts.

7. Hydraulic bending machine section

After the flange is formed, the sheet metal continues to move forward. When the preset bending length is reached, the upper beam presses down, and the folding plate of the bending machine acts to complete the bending of the sheet metal.

8. Maintenance and management of hydraulic system and electrical control section

Regularly replace the hydraulic oil in the hydraulic system, check whether the hydraulic system is running normally, and replace damaged parts in time.

Consult Now

Email:

Service Hotline:

Scan code to consult:

Sales Consultation

After-sales Service Consultation

More News